Lots are used to keep track of specific batches of equipment or parts that you order.

Let's say you ordered 10 pallets of hinges, from different manufacturers. You can create a Lot in EAM that denotes such lot code from the manufacturer and then add it to your transaction (Return or Issue).

Requirements:

- Part should NOT be Tracked by Lot in EAM if the part if tracked by quantity

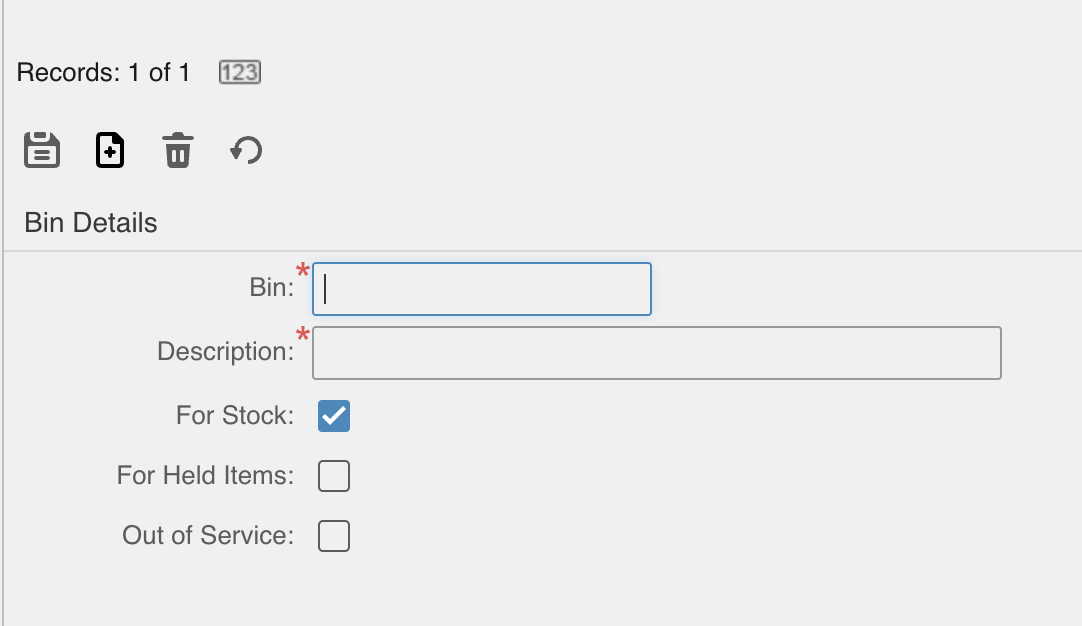

- Lots must be created in advance in Materials > Setup > Lots - (EAM)

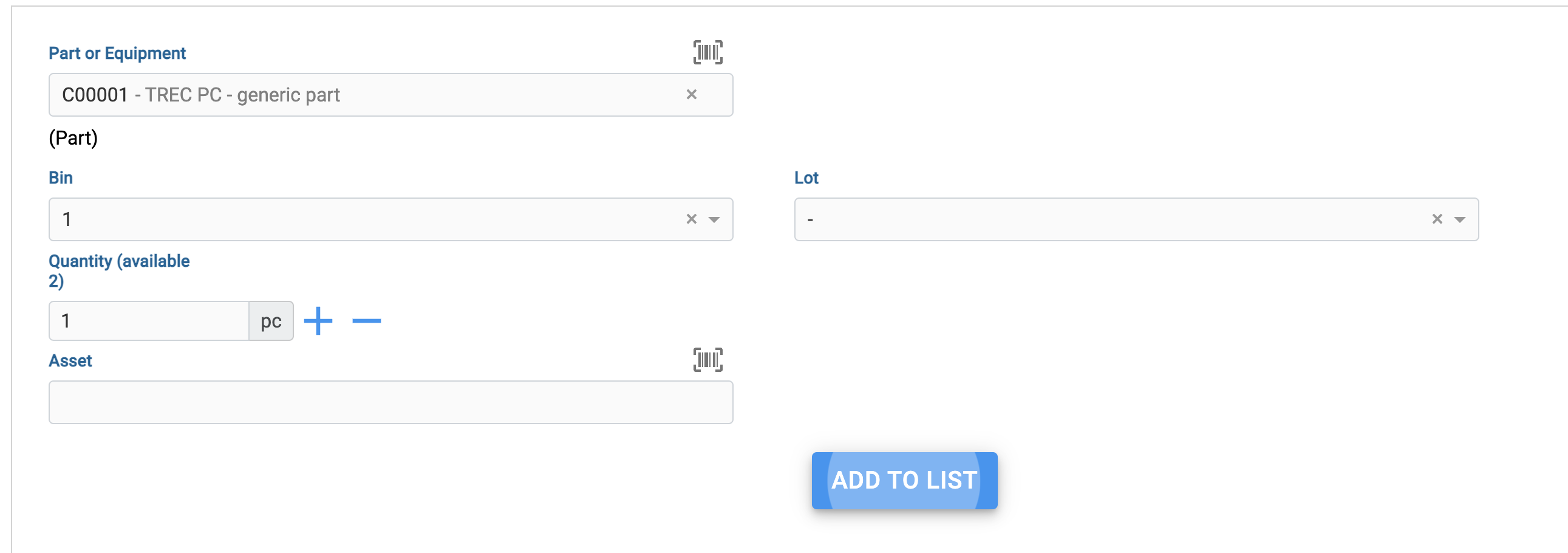

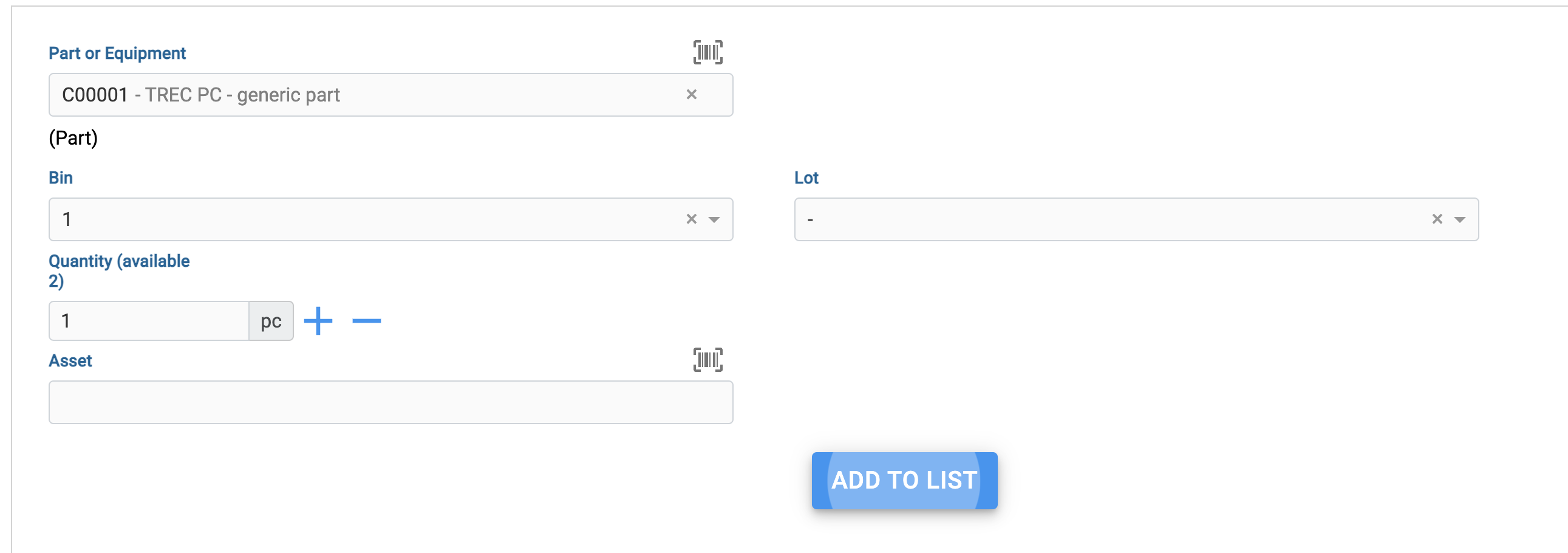

After you receive the tools and put them in your Store, when doing a return transaction, make sure to

1) First select the part

2) Then select the Bin

3) Then select the Lot to which the parts belong. This allows you to put parts of many different lots into the same bin.

If your part is tracked by asset and you wish to handle the lots you should also select the tracked by 'lot'

If your assets also exist and are using a part, you must remote the part reference (only works for assets not in store) and reselect the same part.

This allows entering the correct lot number for the asset